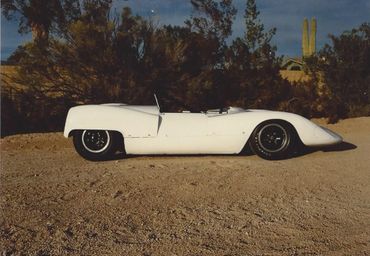

1965 Bobsy SR3 Sports Racer

I was given a great opportunity to restore a 1965 Bobsy SR3 Sports Racer that I found for one of my customers in 1991. What was so special about this car is that it is an American made "Aluminum" tube framed Sports Racer built by Jerry Mong in Medina, Ohio. The Bobsy race cars were a very successful in various sports car events across the country as including claiming National Championships!

An interesting aspect of these cars, as well as other Sports Racers of the era, is that they could be adapted to use a variety of engines and this car in particular was fitted with a 1300 cc Alfa Romeo GTA Junior unit fitted with two Weber side draft carburettors.

A bit of background...

I became aware of this car from a co-worker of mine who had raced it for a time and decided to upgrade it with new bodywork. He had taken the car apart and started the conversion but never finished it. I told a customer of mine about the car and after some inspection and negotiation I obtained the Bobsy on my client's behalf and began the restoration process.

The car consisted basically of the frame, engine and drivetrain as there was no bodywork at all. The car had been sitting for a number of years and although in the dry Arizona climate there was some corrosion, oxidation and dry rot which was to be expected. However, overall the car was in pretty good shape!

The following photos show the car as I got it. Please note the photo of the front frame area which shows part of the frame tubing cut away. The previous owner removed this section to fit the planned new body. I had to fabricate a new front section to replace what had been cut away.

Some Before Photos

Stripped, cleaned up and ready to be operated on!

The first order of business would be to repair the subframe which the following photos will show.

I also disassembled the engine and sent certain bits out for cleaning and machining.

Frame Repair!

A trick to repair tube frames that I learned from Rick Stewart (Stewart Racing Phoenix, Az.) from my Midget and Sprint car days was to machine a spud to fit the inside diameter of the tube to give more strength to the repair. These spuds were rose welded into the frame. The rest of the repair was pretty standard from there.

Subframe restored to original! All aluminum cleaned and polished up and ready for more fabrication, rebuilding and assembly!

Oh...that frame to the right of the Bobsy is a Lotus 51A Formula Ford, but that's another story!

Systems

The following is a brief breakdown of some of the individual bits being restored.

Alfa oil pan with a pretty trick sump. It also had a windage tray. I'm sorry that I didn't take a whole lot more pictures of this engine when I had it apart, like of the Two ring super high dome pistons, the rods and crank and other bits. I'll need to look for more.

The Weber carbs were dusty and dirty but they cleaned up well when I rebuilt them and worked like a charm.

I disassembled the corners and rebuilt the hubs and the brakes.

This car had original Bobsy wheels but the PCD (Pin Circle Diameter) had been altered and needed repair.

The following photos will show where I machined "plugs" to be pressed and epoxied into a larger bore that I drilled in order to work with a round hole. I then milled to surface flat, indexed a new PCD and drilled new holes. No computers or automation was used in this process...I couldn't afford that stuff! I finished off the wheels by polishing the rim and epoxy painting the rest.

Body and Panel Fab and Fitting as well as the Finishing Touches!

The car had no body panels at all when I received it. Fortunately I was able to locate the person who had the original molds for this car and he made me a set of bodywork. As I understand it Jerry Mong's son Ron has his own shop, Elite Fab and Machine in Hilliard, Ohio and may be or have a source for Bobsy bits.

The following photos will show the body parts and some of the modifications and repair needed to fit this particular car. It was very light weight but turned out nice when finished.

The body ended up getting some extensive work but it fit pretty well when all was said and done.

After I finished painting it when all the fit and finish was completed I was fairly satisfied.

A fair amount of aluminum panel fabrication was required such as making a new floor pan, inner wheelwells, various Dzus tabs and brackets and so on.

Here are a few shots of that process and the coming together of the car and of course the finished product!

The Best Part!

There's nothing better than sharing your work with someone who gave you the inspiration and latitude to follow your passion. Thanks Dad!!!

Immortalized in Victory Lane Magazine, March 1991!

Copyright © 2018 ttrs1 - All Rights Reserved.

Powered by GoDaddy Website Builder